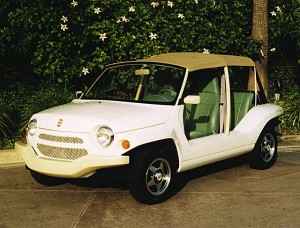

NovaRace, Piontek Engineering, Hurley Racing Products and LincSpeed Design have teamed up to produce the most advanced F600 race car available and we are pleased to announce that the next generation of F600-F500 race cars will be going into production immediately.

The first production car will be developed by our driver team of 2 time National Champion, Brian Novak and the Multi-Divisional Champion, Calvin Stewart. Testing will commence early this summer and production Nova Blade F600s will be available later this year.

How fast are the F600 race cars? These cars are powered by 14,000 RPM 4 cylinder 600CC motorcycle engines with 6 speed sequential gearboxes and paddle shifters. The sound of these cars is absolutely amazing and the F600 lap records are the equal of FF lap records at all kinds of race tracks. And the best part is the cost, all this and at a cost that is less than ½ of a new FF car.

The new Nova F600 Blade is a state of the art design that has taken over a year to complete. The NovaRace design/build team includes our partners:

NovaRace LLC (Jay Novak, overall design)

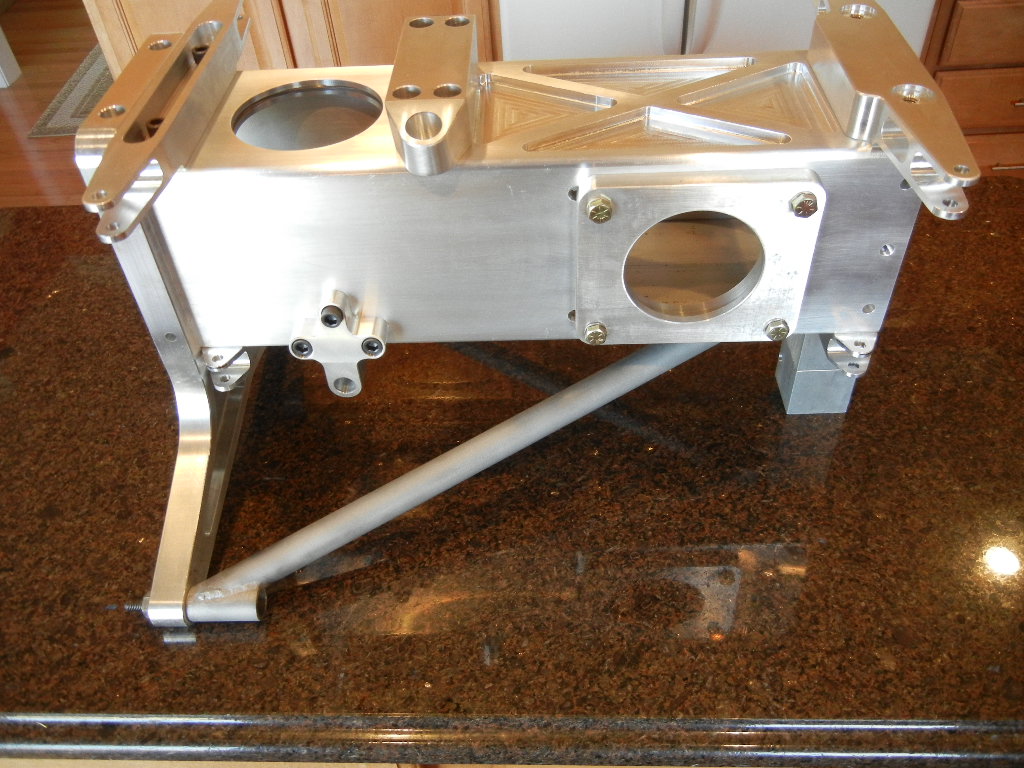

Piontek Engineering (Dave Piontek, chassis design/build)

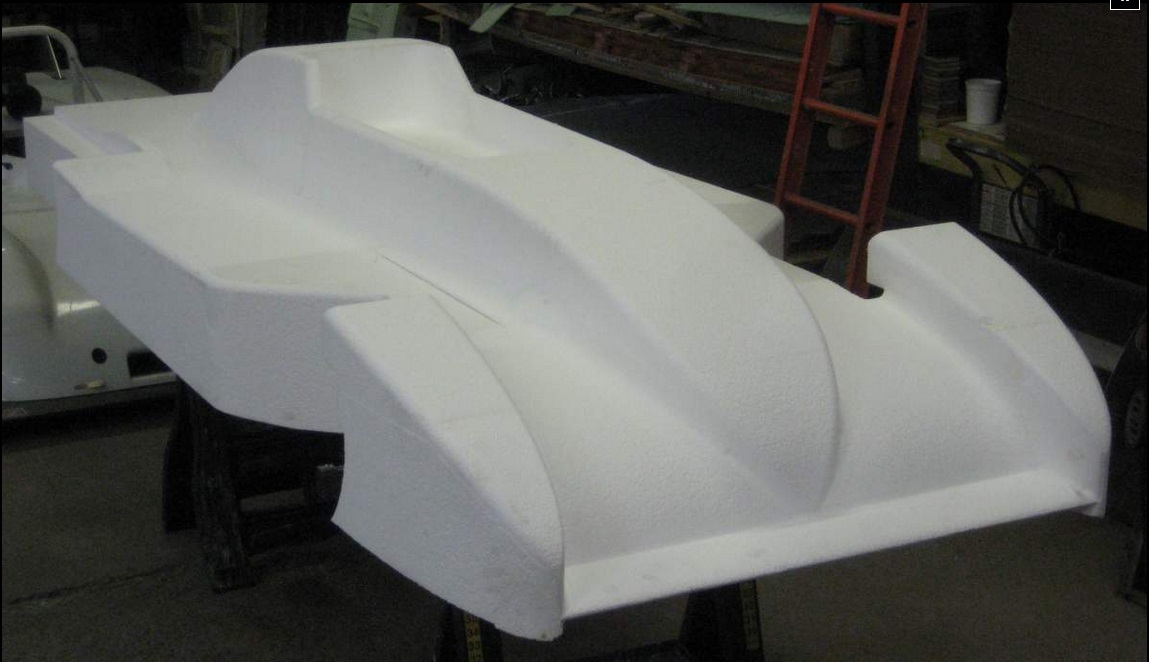

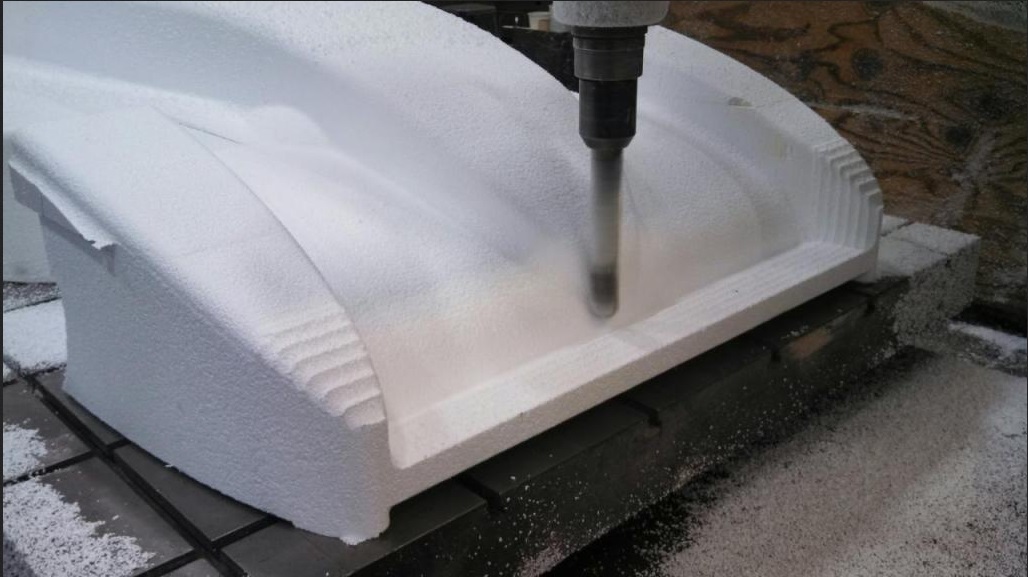

Hurley Racing Products (Mike Devins, body design/build)

LincSpeed Design (Clark Lincoln, body design)

Every member of our design/build team has worked tirelessly over the last year to ensure that the design of this new car has taken advantage of every technology available.

Solid models of every single component have been completed and this includes the body of the car. The design of the body has been developed using the best available solid modeling and CFD technologies. The resulting body is a very significant improvement on our 2007 Runoffs winning F500 and our 2010 ARRC winning F600 car in every respect.

The chassis design of the new Nova Blade F600 has been greatly simplified such that the setup of the car is extremely robust but is still very tunable. The Nova Blade has simple adjustments for all important tuning factors such as wheel rates, corner weights, ride control, ride height and roll couple distribution. The new Blade will tune and adjust just like a conventional open wheel car.

Simplicity of maintenance was a very important factor in the design of the F600 Blade. One of the things that is extremely important to the club racer is the time available to maintain and to prep the car. The design of the new Nova Blade has been focused on improving this very important factor.

The driver package of the new Nova F600 Blade is the best in the business. Many of you who have sat in our previous cars have commented on how roomy the package was. Well the new car is just as good and will certainly fit the bigger racers out there and still make minimum weight.

Nova Blade specifications:

Wheelbase – maximum 80”

Width – maximum 55.0”

Weight – 650 lbs ready to race with steel belly pan.

Chassis – large section tubular steel construction with a .083″ steel belly pan, aluminum belly pan optional.

Brakes – 8” diameter floating front rotors 9.5” diameter floating rear rotor. Wilwood calipers with Nova forged calipers optional.

Wheels – Keizer aluminum wheels with forged 4 bolt centers. Front 10” x 7”. Rear 10” x 8.5”.

Center lock wheels optional.

Bodywork – CFD developed multi-piece fiberglass composite body with structural Kevlar anti-intrusion panels. Carbon fiber body for lighter weight optional.

Engine mounts for late model Suzuki GSX-R600. Optional mounts for other engines as requested.

The first 5 customers will receive their cars as roller assemblies at a cost of $22,000 plus shipping. Add your late model Suzuki GSX-R600cc motorcycle engine with wiring, hook up the cooling package and go racing. The Nova F600 Blade will be the best value in open wheel racing, you simply cannot go faster and have more fun for your $$$$. Get your order in now. Call to discuss options, deposits and delivery.

Dealer inquiries are invited.

Contacts:

National Sales:

Dave Piontek, Piontek Engineering.

Davepiontek2@gmail.com , 810-991-1148

Dealer and Technical inquiries:

Jay Novak, NovaRace LLC

http://www.novaracecars.com/

jnovak@novaracecars.com

313-445-4047

Stay tuned for many more pics as the build of the cars continue.